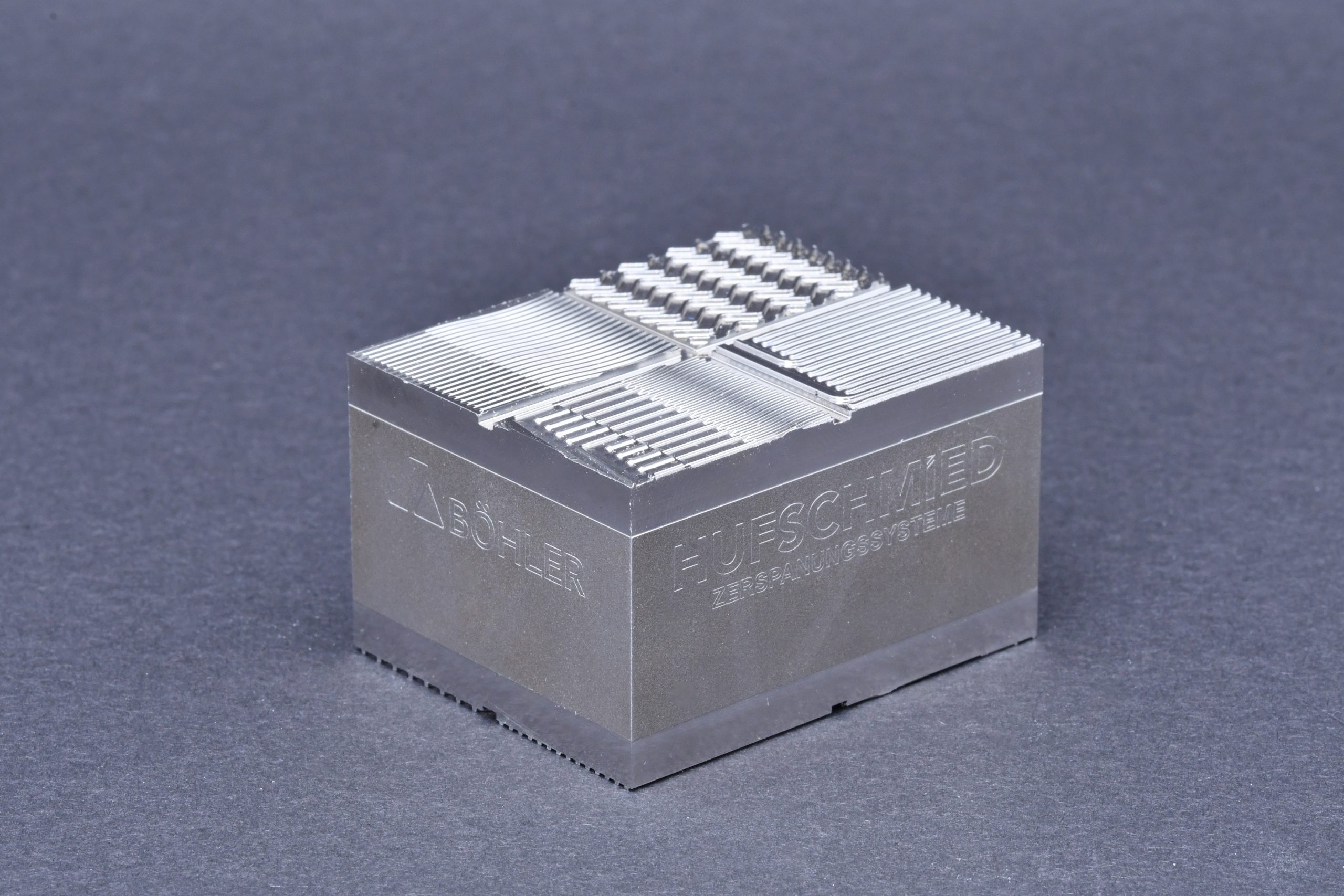

Hufschmied Zerspanungssysteme GmbH is introducing milling tools under the name Bumble-Bi® that make the machining of stamping tools for the production of bipolar plates more economical. The successful series production of bipolar plate stacks depends on these stamping tools, which must have burr-free surfaces with a flatness of <20 μm. The new tool family includes high-feed roughing tools as well as ball and torus tools for roughing and finishing. The Bumble-Bi® tools enable machining strategies with very high cutting pressure.

“Fuel cell technology is one of the keys to sustainable mobility. High production costs have been one of the obstacles to widespread use so far. We saw an opportunity to contribute to more efficient production in the area of mold making,” explains Christel Hufschmied, managing director of Hufschmied Zerspanungssysteme GmbH. “The new Bumble-Bi® tool series, with significantly increased tool life and improved feed parameters, is the result of extensive research and development work. This has been achieved not least through an optimized transition from the tool cutting edge to the tool neck.”

Channels for the reaction gases

The bipolar plate is the heart of every fuel cell. It simultaneously acts as a structural carrier plate and forms the poles of the fuel cell. The anode plate conducts H2, the cathode plate O2. The bipolar plate ensures an even distribution of the reaction gases and conducts them into the reaction zone via flow profiles on both sides. The requirements for embossing tools to produce these profiles are immense. The materials metal, graphite and composite used as bipolar plates must fulfill the requirements for dimensional accuracy and surface quality at very high cycle times.