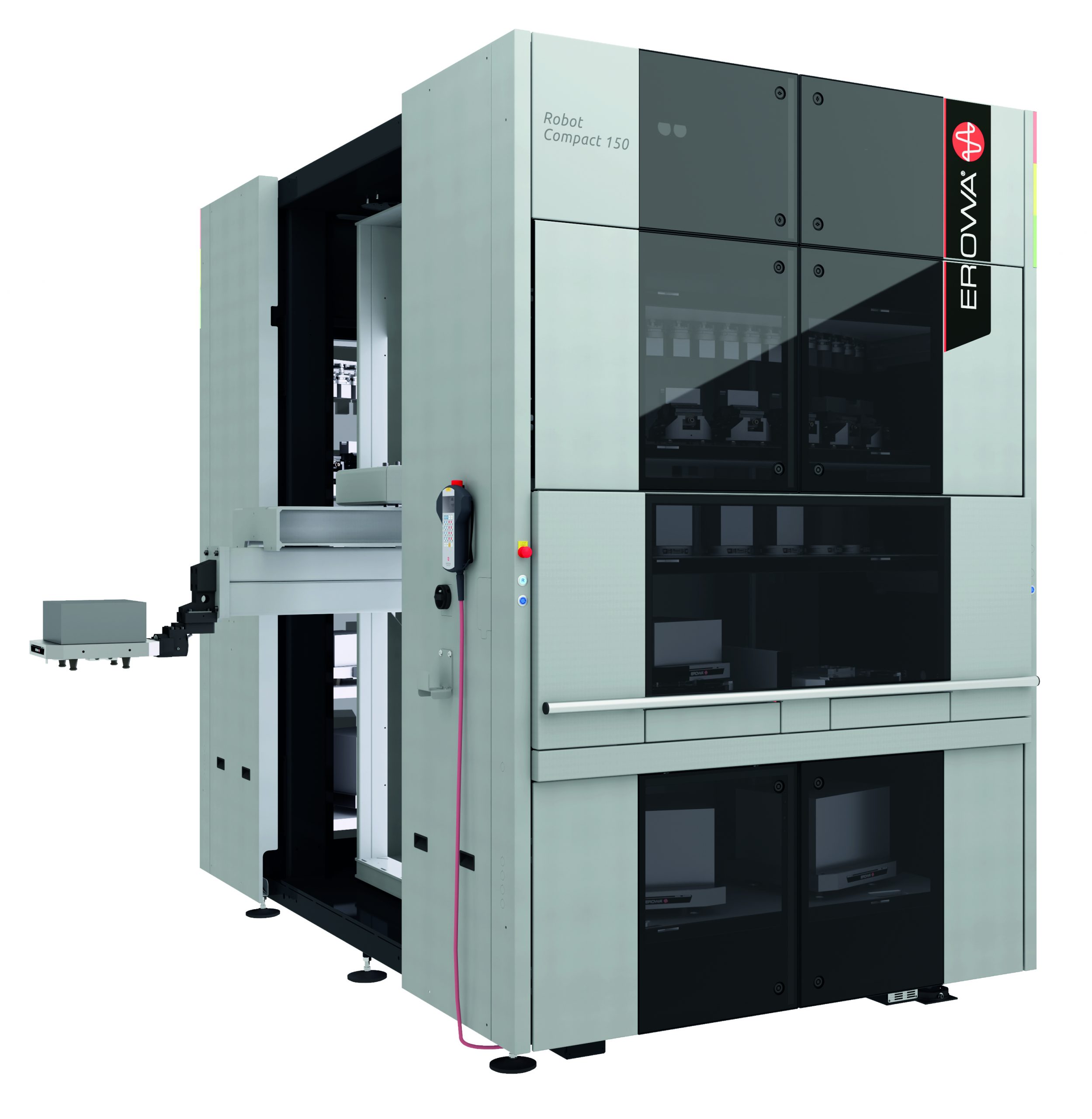

The new EROWA Robot Compact 150 is the logical addition to the EROWA automation portfolio and impresses with its wide range of functions. It is the perfect automation solution for flexible loading of up to two production machines of all processing technologies – from milling to eroding. Thanks to its innovative design, the loader offers an impressive magazine density with a small footprint. Thanks to its compact monobloc design, the robot can be integrated into the existing infrastructure and ready for operation within a short space of time.

Easy to operate

The pull-out magazine levels (optional) ensure convenient loading and unloading of the workpiece carriers directly into the magazine. Thanks to the EROWA EWIS™ chip identification system in combination with the presence sensor, the operator always has a quick overview of the loading of all magazine locations, which significantly increases process reliability and efficiency.

Ergonomic loading station for heavy workpieces

The optional loading station can be integrated to save space. It makes it possible to set up large and heavy palletized workpieces at an ergonomic height while the robot is working. An indexing system enables convenient set-up (4×90° rotation) and locks the pallet automatically when it engages. It also ensures that the pallets do not end up twisted in the magazine.

Extendable magazine capacity and versatility

The magazine capacity of the Robot Compact 150 is flexible and can be expanded considerably. Options such as a third rack magazine or an additional rotary magazine offer solutions for every production environment. The device is capable of handling workpieces of different sizes and heights – from small EROWA ITS electrode holders to large MTS 400 pallets and part heights of up to 400 mm.

Technical details and flexibility

With a footprint of just 4.7 square meters and a transfer weight of up to 150 kg, the Robot Compact 150 offers an extra-long reach of the X-axis. Two independent X-axis drives enable fast magazine handling and a high magazine density with a long reach towards the processing machine. The space-saving gripper trays and the innovative Gripper+ technology (sensor system) ensure maximum flexibility and process reliability.

Overall control with JMS 4.0

The EROWA JMS 4.0 process control system enables comprehensive control and reporting of the entire production process. It offers intuitive user guidance and ensures transparency and efficiency in production.

EMO 2025: Visit EROWA in Hall 12 / Booth D20.