When it comes to demoulding complex undercuts, mould makers often use multi-level tools to clear elements that obstruct the demoulding direction. At Groth in Vlotho, mould makers rely on high-quality latch locks from the extensive range of their standard parts partner, KNARR, to drive such tooling solutions.

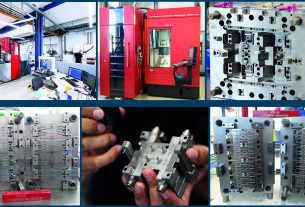

The Claus Groth company, based in Vlotho, East Westphalia, has been manufacturing complex and technically sophisticated injection moulding tools since 1948. In addition, the plastics specialists produce injection-moulded products in their in-house moulding facility. As a family-run business, Groth is a reliable partner for clients in the automotive industry, mechanical engineering, furniture construction as well as transport technology.

The company’s production experts can respond flexibly to customer requirements – from just a few hundred parts per year to production volumes of up to two million. “We manufacture injection moulds up to a size of 800 x 600 mm,” explains Jens Strate, Managing Director of the company located in the Lipper Bergland region. “Our injection moulding machines operate with clamping forces of up to 300 tonnes. And for over 30 years, we have also been supplying our customers with assemblies and plastic-metal composites.”

The majority of products are technical components

Groth currently employs 32 staff members. In production, six specialists per shift oversee the 20 machines, which operate in two shifts. Four specialists work in toolmaking, while five are responsible for assembly. The material receiving, storage, and shipping departments each have two employees. The remaining staff members work in sales, management, and administration. For design work, the company relies on experienced external specialists, and electrode manufacturing is also handled by trusted external partners.

The toolmaking department primarily processes standard tool steels, as well as case-hardened materials and occasionally stainless steel. Typically, the mould specialists manufacture tools with four or eight cavities, designed for continuous operation and almost exclusively used in their own injection moulding facility. The tools are engineered for high process reliability and stability, meeting stringent quality standards. Tolerances of 10 µm or less are the benchmark.

Creative Solutions for Complex Manufacturing Tasks

The majority of injection-molded products are technical components, many of which are made of polyoxymethylenes (POM). These high-molecular, partially crystalline thermoplastics are generally used for the production of precision parts, not least because of their high rigidity, low friction values and good dimensional stability. However, other technical plastics are also processed on a large scale in Vlotho.

The team around Strate often finds creative solutions for their clients. Especially when the workpieces have geometries that place high demands on the injection mold and especially on the demolding. For example, when complex geometries with undercuts in the demolding direction are to be produced. Then the task of demolding such parts quickly and gently is often a real challenge. Generally, tool and mold makers use sliders or jaws when undercuts, notches or openings on injection molded parts cannot be reliably demolded using conventional mold separation.

Project with Three Different Diameters

In a recent project, the plastics specialists manufactured three very similar components for chassis applications, differing only in their dimensions. The diameters measure 62, 67, and 68 mm.

For this task, the toolmakers built three four-cavity moulds with multiple parting lines, enabling the simultaneous injection moulding of four identical black POM components per cycle. The exact order quantities are yet to be determined by the client, but Groth’s moulding facility is fully prepared for series production and exceptionally well-equipped.

Demoulding as a Challenge

‘We then complete these parts in the assembly with an O-ring seal made of softer, more elastic TPE material, which is firmly affixed to the POM part using adhesive dots,’ says Strate, describing the assembly to be manufactured. ’The O-ring seal is in contact with the metal of the vehicle and absorbs any small relative movements of the components to each other, which may arise, for example, due to vibrations when driving. This also helps to prevent unwanted noise, among other things.’

One challenge in the injection moulding and subsequent demoulding is the deep ribbing of the products – but also the undercuts, which could not be demoulded with a classic open-close mould design. ‘These areas are partly located in the depth of the cavity of the injection mould,’ says Strate, outlining the challenge for the toolmakers. ’We therefore decided to free the undercuts of these plastic products with the help of underfloor slides. In addition, an inner core must also be pulled out for demoulding.’

Safe Ejection for Complex Components

Underfloor slides are slides, but also core pulls, that the mould maker has installed below the parting line. They ensure that the undercuts are released just before the mould is actually opened. Underfloor slides are often moved with hydraulic cylinders, especially in larger tools. However, this type of drive is too complex and also too prone to error for smaller moulds. Other variants are generally used here.

‘A proven method of pulling the slide gates in particular before demoulding is to drive them via an additional plate in the mould,’ explains Strate. ’This is activated before the parting line is opened and the resulting movement ensures that the slide gates release the plastic parts. This means that they can be easily removed from the nozzle-side mould half when the mould is actually opened at the parting line.’

Two Latch Locks Control the Movement

Four identical parts are produced in the injection mould with each shot. The cycle times are around 55 seconds. In the project for the three moulds for the chassis component, the moving plate is precisely controlled by two latch mechanisms, which are installed in the centre at the top and bottom of the injection moulding tool.

‘The two latch units ensure that the mould’s parting line initially remains closed until the platen that drives the underfloor slide gates has reached its end position,’ explains Strate. ‘Only then do the two latch slides release the opening of the tool at the actual mould parting line, the injection-moulded part is demoulded on the nozzle side and finally ejected on the ejector side and removed by a robot.’

KNARR Has an Excellent Reputation in the East Westphalia Region

The latch locks for all three tools come from the standard parts specialist KNARR, based in the Franconian town of Helmbrechts. KNARR originally specialised in ejection technology. While still a leader in this area, it has since expanded its portfolio to offer a complete range and has been able to convince many users, particularly in the East Westphalia region.

“We’ve had a very collaborative business relationship with our standard parts partner KNARR for many years,” emphasises Strate. “The close contact with the field service plays an important role here, but above all, it’s the high quality and durability of all components. We can rely on that. We can be sure that wear and tear on the latch lock units will not be a problem in the foreseeable future.”

Quick and Simple Installation

For the precise control of the movements in this tool, the high-quality latch locks from KNARR are the key factor. The compact, pre-assembled unit enables the toolmakers to install it quickly and easily into the injection mould. Depending on the application, the control elements are available in both an on-mounted and pinned version as well as a recessed and inserted version. The team at Groth opted for the on-mounted solution for these three tools.

In product development at KNARR, the developers placed great importance on sensible installation dimensions and practical standard size definitions. KNARR configures the control bracket and latch bar to customer specifications in terms of length and with the necessary mounting holes. For the standard sizes, the standard parts manufacturer delivers the latch locks completely ready for installation.

Individual Configuration of Components

All components were packed together and delivered ready for assembly to the toolmakers. The external designer commissioned by Groth obtained the 3D data for the standard latch locks from KNARR’s portal and adapted them precisely to the application. The machinists at Groth then shortened the latch bar made of nitrided 1.2312 to the correct length and also carried out the precise alignment.

“In processing, it becomes clear that KNARR supplies high-quality components here – you get a good feeling working with their products, you can feel the quality. This applies to both the material and the precise workmanship. And the accompanying data fits exactly. Then there’s the ease of handling during mounting – as the latch lock is already pre-assembled, KNARR eliminates the otherwise laborious task of assembling a ‘latch lock kit.”

High-Quality Components Ensure Optimal Function

With carefully coordinated materials and coated components, KNARR guarantees minimal wear of the latch locks, optimised service life, and thus significantly reduced maintenance. The fast opening and closing of the injection mould in a purely mechanically driven tool solution also allows for the minimisation of cycle time. A latching system on the latch lock, which locks the backing plate in position and thus prevents possible collisions, ensures a stable production process.

“We can rely on the high quality of the standard parts, the ability to deliver, and the professional advice from our standard parts partner KNARR,” summarises Strate. “Although we also source material from other suppliers, KNARR is our go-to full-service supplier, especially for our smaller tools. We know that everything is taken care of and everything will fit, and we feel in good hands with our standard parts partner.”

Richard Pergler