A leading Chinese company in the medical sector operates a plant in Shenzhen specialising in mouldmaking and injection moulding of components for breathing machines. For more than ten years, the company has relied on standardised components from HASCO and has successfully been using HASCO positive locking cylinders Z2302/… for the liquid silicone rubber (LSR) moulding of respiratory masks.

The company’s main products are breathing machines, including CPAP and BiPAP machines, masks, and accessories for the treatment of, for example, sleep apnoea, as well as hospital applications. The Shenzhen plant specialises in breathing masks such as advanced mask designs, full-face, minimal-contact, pillow and paediatric masks. In most cases, these products are made from polycarbonate and liquid silicone rubber. The company not only produces and assembles respiratory masks, but also manufactures the moulds for LSR processing in-house. If a mask consists of thermoplastic components, such as polycarbonate, and LSR sections, pre-fabricated thermoplastic parts are inserted into the LSR mould.

Around 60 of the 900 employees at the Shenzhen factory work in the tool shop. The masks are supplied directly to the global market and to hospitals. Using a total of 200 LSR injection moulding machines, ranging from 1,000 to 3,000 kN, located in Shenzhen and at a plant in Costa Rica, the company produces approximately five million masks per year. Production typically uses two- and four-cavity moulds, as well as 16- and 32-cavity moulds. Typical cycle times range from one to two minutes.

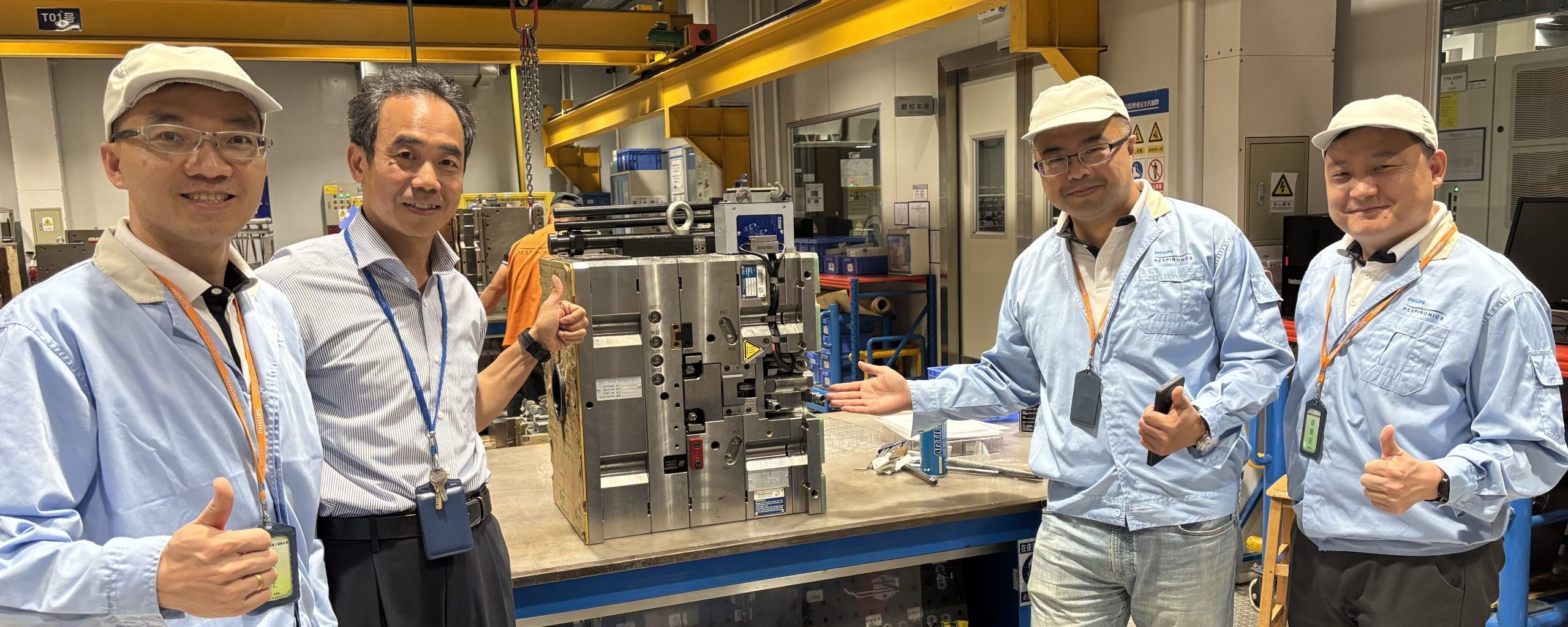

“For more than ten years, we have been using HASCO products,” says the company’s Tooling Manager, “including components for temperature control systems, ejectors, guiding elements and hydraulic cylinders. We are very satisfied.” In particular, he appreciates the competitive pricing, short lead times and consistently high quality. “In China, it is difficult or even impossible to obtain comparable components,” he adds.

For LSR processing, the customer is now also using HASCO’s positive locking cylinders Z2302/… to operate valves, cores and similar components. In the past, conventional locking cylinders were significantly larger and had to be mounted on the platen. During mould changeovers, these cylinders had to be removed, which often led to leakage and additional work. HASCO’s positive locking cylinder Z2302/… is very compact and can be installed directly into the mould. As a result, the cylinders do not need to be removed during mould changes. This not only prevents leakage but also significantly reduces mould changeover time, resulting in cost savings. While a mould change previously took around one hour due to the disassembly of conventional locking cylinders, it now takes only a few minutes, as the Tooling Manager explains.

“Even if we operate ‘only’ 20 different moulds across our 200 machines, the moulds have to be changed about once a month. This is done for quality inspections and to clean off a type of patina build-up,” he explains. In addition, because the mould assemblies are more compact overall, smaller injection moulding machines can often be used. The robust design of the positive locking cylinders, combined with precise final-position sensing via proximity switches, ensures secure locking of the piston rod and makes them suitable for use with core pullers and mould slides. Operating temperatures of up to 180 °C make them ideal for LSR processing.

The positive locking cylinder features optimised seals and is easy to install. The integrated positive locking mechanism eliminates the need for a separate locking device on the mould. The cylinder can be mounted using either the HASCO flange Z2310/… or the HASCO groove-nut set Z2311/…, which also allows fine adjustment. As the Tooling Manager is highly convinced of the compact HASCO locking cylinders, he plans to use them in all new LSR moulds, including replacement moulds for older tools that will be phased out after five to six years of service.

He is also keen to learn about other new HASCO developments. For example, he plans to use the HASCO Identity Check for the clear identification of HASCO original products. “Of course, we will visit this customer regularly to introduce all our new products,” promises Louis Yu, CEO of HASCO Trading (Shenzhen).

More information: www.hasco.com