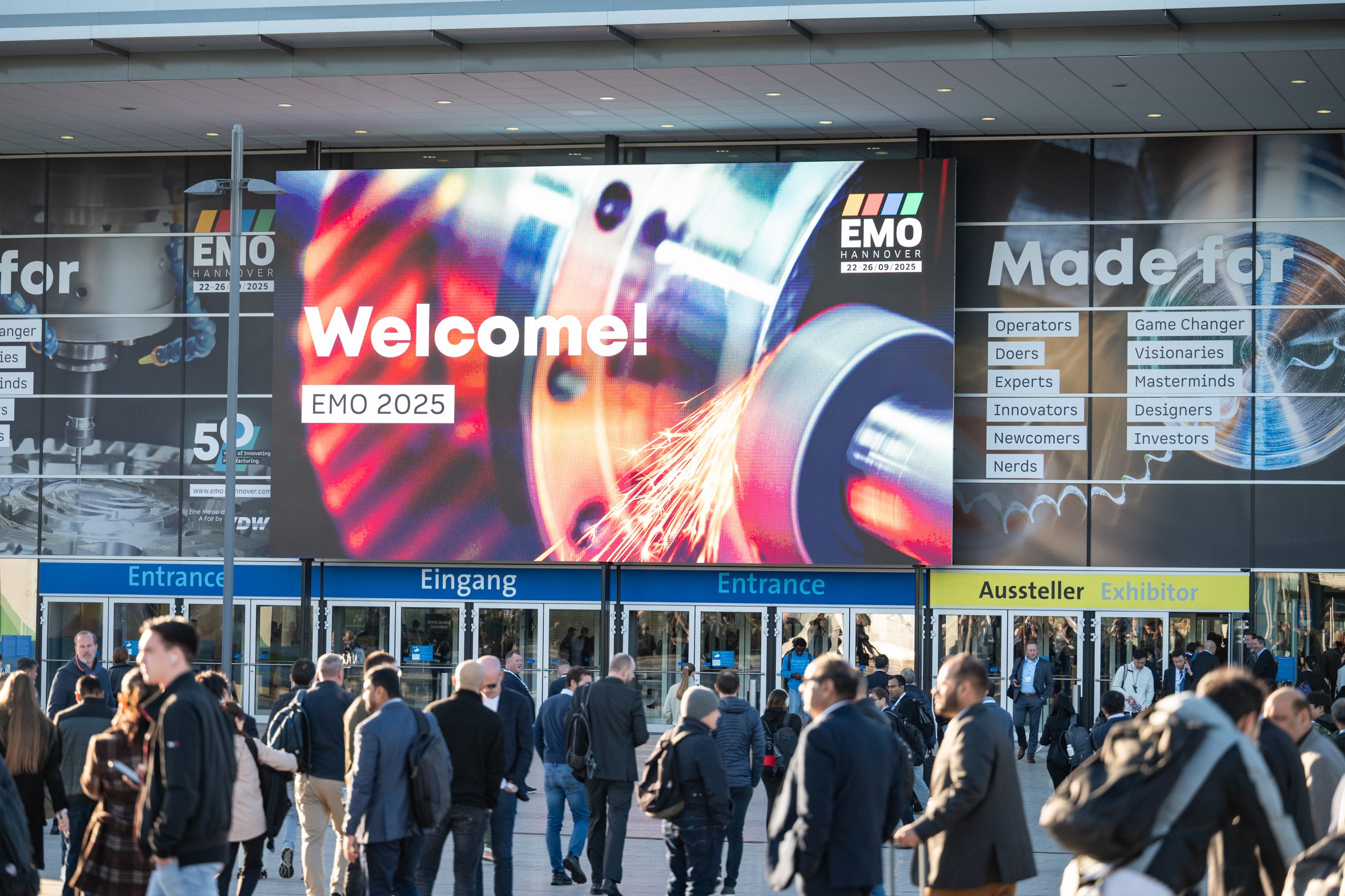

The whole world of metalworking – for five days, Hannover was the venue for EMO, the world’s leading trade fair for production technology. Attracting a number of 80,000 trade visitors from all over the world, the exhibition grounds provided important innovative impulses for greater competitiveness in the industry. The main focus was above all on the topics of automation and artificial intelligence, which have once again found their way into industrial processes as drivers of pro-duction efficiency.

Technology, information, exchange, international networking, and cooperation – this is what EMO has embodied for 50 years. More than 1,600 exhibitors from 45 countries and a diverse supporting program presented a host of solu-tions for modernizing and upgrading production.

“There is a profusion of smart and impressive technical solutions. This EMO has convincingly demonstrated that,” says Carl Martin Welcker, General Com-missioner of EMO 2025. “For them to be effective, the booster engine of in-vestment now really needs to fire. Many projects are in the pipeline after three years of investment restraint, but the uncertainty in the political sphere contin-ues to put the brakes on investment,” Welcker continues.

Confidence is already picking up abroad, particularly outside Europe. In the visitor survey, two thirds of visitors from there state that they intend to invest. In Germany, the figure is less than half. This is reflected by the current trend in foreign orders placed with the German machine tool industry, which increased by 6 percent in the first seven months of 2025 compared to the same period of the previous year. Demand from Germany fell by 22 percent over the same period. Nevertheless, EMO exhibitors are reporting sales. Norbert Teeuwen, Managing Director of Okuma Europe says: “Open Possibilities – that is pre-cisely what connects EMO and Okuma. Our appearance at the exhibition was a complete success – among plenty of sales, we even sold three exhibition machines directly off the booth to our customers. For us, EMO is always a highlight. Thank you!”

Automation is a hot topic in the industry

The big topic in the industry is automation. This is driven by costs and a short-age of skilled workers. 50 percent of the visitors surveyed are interested in how they can use automation to boost their productivity. “Automation is every-where here and is going to make a big difference,” says Aaron Morrill, CNC mechanic from the USA. The importance of the use of robots is growing, as numerous robot manufacturers have impressively demonstrated at EMO. Ralf Winkelmann, CEO of Fanuc Europe, says: “We also see that robots will become increasingly important in the machine tool industry. Industrial robots will coexist with human operators. In the future, they will provide the most efficient solutions.”

Interfaces to digitalization and sustainability

More than a third of the trade visitors want to learn about new aspects of digitalization and AI. “We see added volume in processes where all the possibilities for processing data from sensors are utilised. AI is useful for this and improves quality in the factory,” says Jan Otoupakik, CEO 4dot Mechatronics, a startup from the Czech Republic. This was also reflected in the popularity of the P.O.P Talks, which were held daily at the central innovation stage, and highlighted numerous aspects of AI in production.

Automation, digitalization, and artificial intelligence ensure higher productivity, efficiency and quality. This also increases sustainability in production, for example by promoting efficiency in energy and materials. Sustainability is an important factor in research and among talented young people. “We are working on various solutions. One very important example is to reduce the energy consumption of production systems, for example by reducing the coolant flow so that only as much coolant as necessary is used, rather than as much as possi-ble. That was the strategy in the past. This allows us to save up to 95 per cent of the pump energy, electrical energy and up to 60 per cent of the total energy consumption of the production system. So, this is a big step forward,” says Professor Berend Denkena from the Leibniz University Hannover.

Top platform for international managers

Once again, EMO has proven to be a top platform for managers and buyers. In the visitor survey, more than half of the respondents stated that they were top or middle managers. They also have the authority to make procurement decisions.

Overall, 94 percent of visitors felt their objectives for the visit had been achieved. 98 percent rated EMO between satisfactory and very good. This is also reflected in the verdict of the exhibitors. Irene Bader, Board Member at the German-Japanese company DMG Mori, puts it in a nutshell: “What we presented at EMO in 2025 is a glimpse into the future of production. Our cus-tomers‘ enthusiasm and their valuable feedback have once again shown us how important face-to-face exchange is for real innovation. For five days, EMO was a global meeting place for ideas, partnerships, and new perspectives.” And German Wankmiller, Chairman of the Board of Management of Grob-Werke, adds: “Overall, we are satisfied with how this year’s EMO went, and we’ve been positively surprised considering the currently challenging market situation. The number of visitors and the quality of the discussions have also been consistently positive and have given us important ideas to follow up over the coming months.”

“Once again, it has proven possible to attract international market leaders in metalworking to EMO and address the new topics in industrial production,” concludes Dr. Markus Heering, Executive Director of the EMO organizer, the VDW. “As a result, it has consolidated its position as the world’s leading trade fair and barometer of trends,” he summarizes.

EMO 2027 will take place from October 4 to 8 in Milan, Italy.

Exhibitor feedback from EMO Hannover 2025

4dot Mechatronic Systems s.r.o., Czech Republic, CEO Jan Otoupakik (Startup Area)

We see added volume in processes where all the possibilities for processing data from sensors are utilised. AI is useful for this and improves quality in the factory.

DMG Mori AG, Germany/Japan, Board Member Irene Bader

“What we presented at EMO in 2025 in the DMG Mori World is a glimpse into the future of production. Our customers‘ enthusiasm and their valuable feed-back have once again shown us how important face-to-face exchange is for real innovation. For five days, EMO was a global meeting place for ideas, part-nerships, and new perspectives”

Emuge-Franken, Germany, Managing Director, Gerhard Knienieder

For us, EMO Hannover is much more than just a product show – it is a global meeting place for movers and shakers. The direct exchange with many international customers and partners at our stand once again proved very valuable for us.

Fanuc Europe Corporation SA, Luxemburg, CEO Ralf Winkelmann

We also see that robots will become increasingly important in the machine tool industry. Industrial robots will coexist with human operators. In the future, they will provide the most efficient solutions.

Stefan Simic, Leiter EMD toolshop leader (trade visitor from Serbia)

I think AI is very important and that it is something that we cannot escape. We need to embrace it and learn to live with that because that is the future.

Grob-Werke GmbH & Co. KG, Germany, Chairman of the Board of Management German Wankmiller

Overall, we are satisfied with how this year’s EMO went, and we’ve been posi-tively surprised considering the currently challenging market situation. The number of visitors and the quality of the discussions have also been consistently positive and have given us important ideas to follow up over the coming months.

Hainbuch GmbH, Germany, Production Division Manager Stefan Nitsche

EMO 2025 was once again exactly the right platform for us to present our latest developments to an international trade audience. Nowhere else do we meet so many decision-makers who are specifically looking for innovative solutions

Leibniz Universität Hannover, Germany, Professor Berend Denkena

We are working on various solutions. One very important example is to reduce the energy consumption of production systems, for example by reducing the coolant flow so that only as much coolant as necessary is used, rather than as much as possible.

That was the strategy in the past. This allows us to save up to 95 per cent of the pump energy, electrical energy and up to 60 per cent of the total energy consumption of the production system. So this is a big step forward.

Okuma Corporation, Japan, Managing Director of Okuma Europe GmbH, Norbert Teeuwen

Open Possibilities – that is precisely what connects EMO and Okuma. Our appearance at the exhibition has been a complete success – among plenty of sales, we even sold three exhibition machines directly off the booth to our cus-tomers. For us, EMO is always a highlight. Thank you!

Paul Horn GmbH, Germany, Managing Director Markus Horn

EMO Hannover is the central point for us to meet customers and partners from all over the world. As an international meeting place, it plays an indispensable role in innovation and face-to-face discussions with our customers. EMO 2025 has been a complete success for us, and we are looking forward to the next one.

Siemens AG, Germany, Stand Manager Dominik Riehle

The response to our presence at the trade fair was overwhelming – a particular highlight was the launch of our data alliance with leading machine tool manufacturers, which is paving the way to revolutionary AI solutions in the pro-duction industry. It was not only the large number of visitors that was impressive, but above all the decision-making competence and specialist knowledge of our discussion partners. The commitment to encouraging young, talented people was also tangible: The picture was characterized by a lot of interest from young people and strong initiatives to generate enthusiasm for the industry. We actively support this – among other things through the Special Education Show and the German Skills Competition.

United Machining Solutions, Switzerland, CEO Stephan Nell

The launch of our new United Machining Solutions Group at this year’s EMO was a resounding success. We have been delighted to receive consistently positive feedback from the numerous visitors. In addition, we have already set a new record for incoming orders – a strong signal for our joint future.

Wohlhaupter GmbH, Germany, Managing Director Frank Wohlhaupter

This year’s EMO Hannover once again provided us with the ideal platform to meet our international customers and partners. I was particularly pleased that the quality of visitors to our stand was again very high, especially those from Europe.