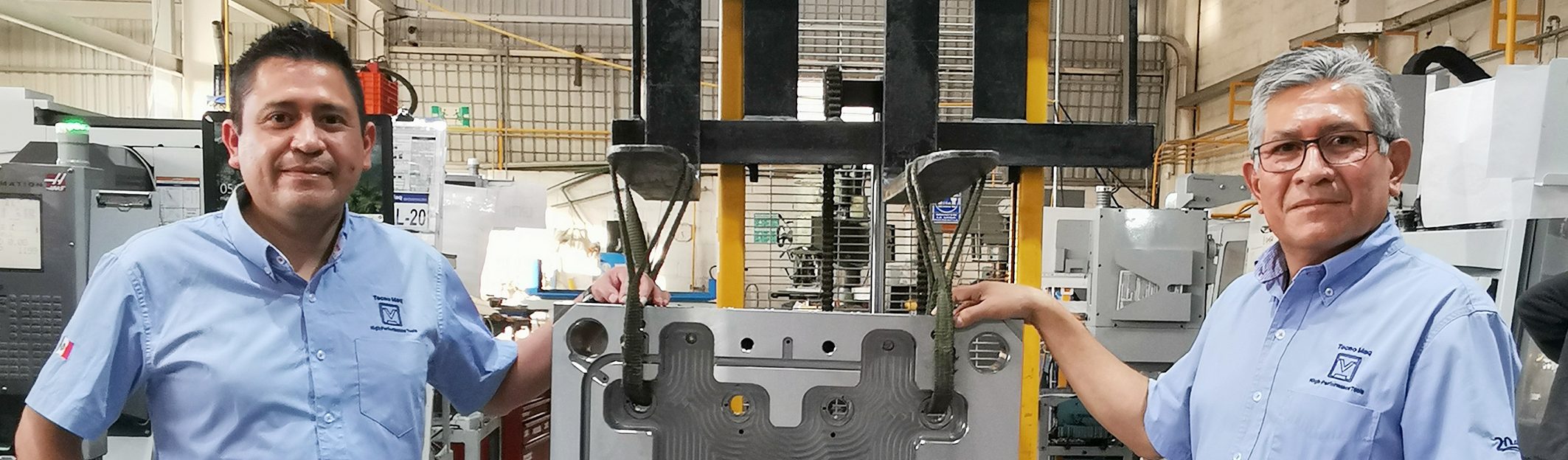

By introducing standard components into its production process, the Puebla-based company Moldes TechnoMaq, which has established a reputation in Mexico for manufacturing blow moulds and injection moulds, has become more productive and efficient in its manufacturing processes.

Founded in 1998, the family business initially offered engineering and machining services for the plastics and packaging industry. Over time, the need for mouldmaking experience was discovered in the market, particularly in the packaging and automotive sectors. “This gave rise to the dream of building moulds in Mexico – and high-quality moulds at that. I can proudly say that I have fulfilled this dream. Step by step, we have produced increasingly complex moulds. Our customers confirm their satisfaction and reward us with their loyalty,” says Raúl Tello Espinosa. Today, Managing Director Raúl Tello Espinosa and his son Víctor Tello Carrera as Technical Director run the company. “When my son joined the company, we made the biggest leap forward. I’m good at mechanical issues, but he brought new perspectives in terms of design, software use and automation. That’s how we became a great team,” says the company founder.

The integration of standard components offers the company additional valuable resources to increase productivity and efficiency and to offer customers higher quality products. The support of HASCO México was crucial in the transition from traditional mouldmaking, where all components were still manufactured in-house, to the use of standardised standard parts such as the A8001 clamping device. This change has enabled Moldes TecnoMaq to focus its resources on truly value-adding activities and drastically reduce delivery times.

At the beginning of the pandemic, when demand for moulds for the production of antibacterial gel and detergent bottles and the associated closures was booming, Moldes TecnoMaq relied on the use of standardised components from HASCO to maximise its production capacity. The company delivered more than 70 tools, including injection and blow moulds, in record time. Today, as demand has stabilised, resources are increasingly being put into more sophisticated and complex projects. Moldes TecnoMaq had traditionally focused on the manufacture of tools, producing every single component itself.

They looked for reliable suppliers and found HASCO. “We now rely on HASCO for the procurement of plates and all standard accessories for mouldmaking. This eliminates all the preparation steps – a process that used to take two to three weeks – so that we can now concentrate on machining the housings for cavities, cores, inserts and all essential parts of the mould.” According to Víctor Tello Carrera, one immediate benefit is the reduction in processing times. The ability to work with standardised parts is also a major advantage for customers. “This means that our moulds can be used anywhere in the world, as they are built from standardised components such as those from HASCO. This is a benefit because our customers don’t have to worry about sourcing spare parts for their moulds as they are readily available everywhere. In addition, maximum accuracy in terms of tolerances and dimensions are guaranteed.”

Moldes TecnoMaq also found another way to improve the machining processes. “Our traditional method was to place the mould assembly on the worktable and make all the adjustments and alignments before the process started. After analysis, we realised that we were wasting a lot of time setting up and needed to reduce lead times and optimise manufacturing costs. We approached HASCO and explained our problem. With the A8001 clamping device, HASCO had a solution that offered numerous advantages, such as a drastic reduction in set-up times, greater mould precision, shorter delivery times, better machine utilisation and greater efficiency in the machining area,” explains Raúl Tello.

Carlos Rosales, HASCO’s technical sales engineer responsible for the south-east region, has supported Moldes TecnoMaq from the very beginning with the introduction of the standard parts and the use of the clamping device. The A8001 clamping device from HASCO was developed to securely fix and precisely align plates. It offers horizontal and vertical machining options for all standard tool dimensions. In addition, the high-precision positioning of centred housings ensures a repeat accuracy of 10 µm thanks to reduced tolerances, and with the three standard sizes of the A8001 base plate, all tool dimensions from 156 x 156 to 596 x 796 mm can be handled.

For his part, Raúl Tello assures that by using the A8001 clamping device, a safe, precise process with numerous advantages has been achieved. “This plate has become an indispensable tool for us. We have focused our efforts on producing increasingly complex moulds with higher added value. This has made us a more profitable workshop with better competitive advantages.”

“With the focus on standardisation, we are on a different level in mouldmaking. Initially, we were a little sceptical about taking the leap and clung to our habits. But once we took the chance, we immediately saw the difference,” comments Víctor Tello Carrera. The focus is currently on implementing new systems and software to enable complete traceability of moulds and their manufacturing processes. This will help to recognise potential errors and problems or identify bottlenecks in the process.

HASCO, certified in accordance with quality standard DIN EN ISO 9001, comprehensively labels its products for complete traceability. This clear labelling provides users with the highest level of certainty for distinguishing between original products and counterfeits when taking into account given specifications. “We respond to our customers‘ trust with innovation. This drives us to constantly develop new technologies, cooling systems, connections, software and process improvements – everything that has to do with mouldmaking. That is the key to our success,” says Raúl Tello.

Víctor Tello emphasises that the company’s growth strategy goes beyond delivering a mould to its customers – it’s about delivering a solution that includes design, service, support and validation. When Moldes TecnoMaq celebrated its 20th anniversary, it was a good opportunity to reflect on the journey that has taken them from their beginnings in a small room in the back of the family home to the structured company they are today. The focus remains on customer service and technological excellence, contributing to the development of mould making in Mexico.

HASCO, the pioneer of mouldmaking for more than 100 years, supports its customers worldwide from the idea to production with competencies such as innovative strength, agility, simplicity and performance.

Extract of the article published by Plastics Technology México.